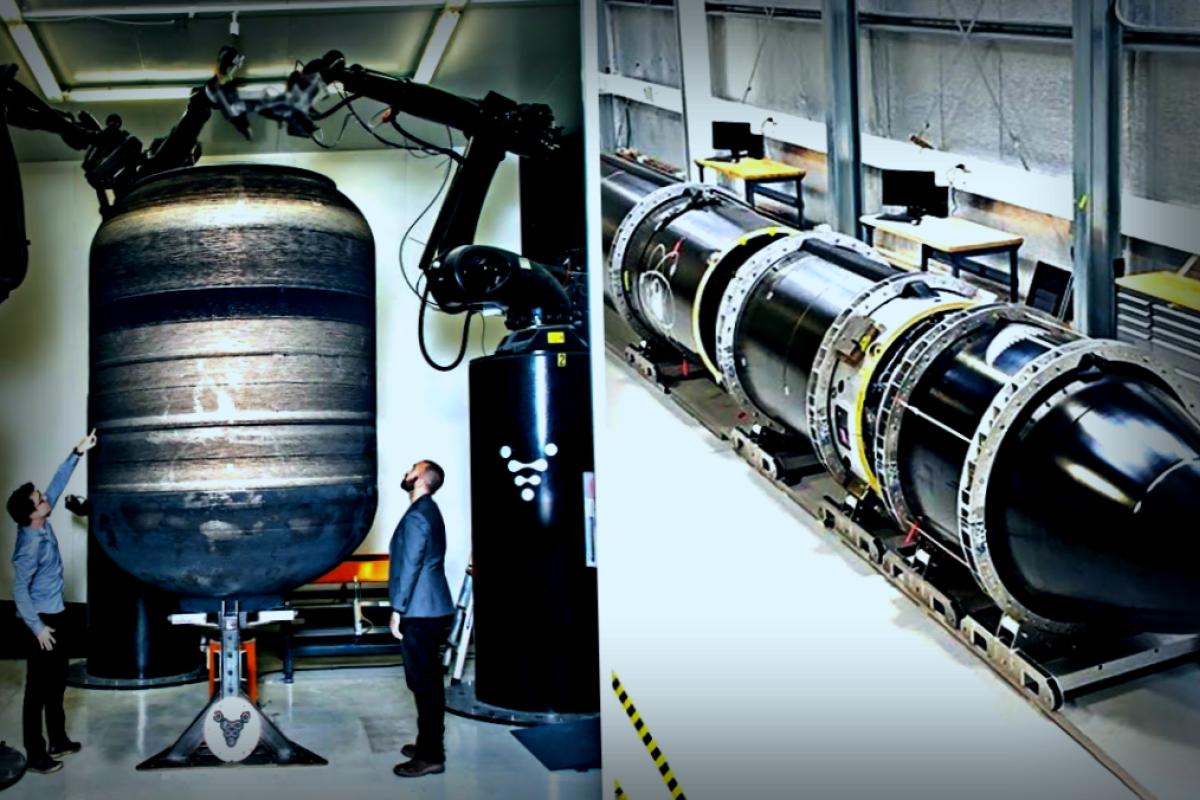

The world of rocket science is undergoing a major makeover thanks to 3D printing. This innovative technology allows for space launches to be done on demand and pushes the capabilities of what’s possible in rocketry. For instance, Agnikul, a pioneering firm based in India, is using 3D-printed rocket engines to dramatically boost production efficiency and slash costs. Recent breakthroughs put a spotlight on how 3D printing is flipping the aerospace industry on its head.

The Importance of 3D Printing in Rocket Production

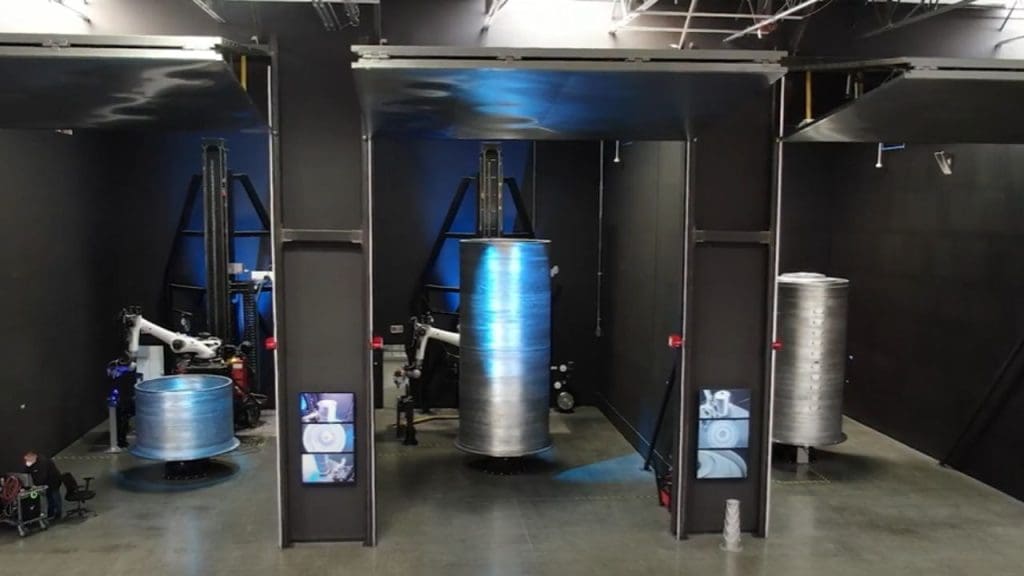

3D printing is crucial for crafting intricate rocket components, which would be tough to create using standard manufacturing methods. It opens the door to unique designs that enhance rocket performance and dependability. An article from MSN notes that being able to produce these components with both speed and accuracy is revolutionary and is pushing the innovation limits in rocket design.

Another game-changer is how much production time and costs can be reduced with 3D printing. As reported by IEEE Spectrum, firms like Agnikul harness 3D printing to streamline their processes, cutting the time it takes to develop rocket engines significantly. This not only makes it cheaper but also speeds up the whole production line, making it simpler to test out new rocket technologies quickly.

Plus, using 3D printing creates lighter and more efficient components, which fosters better fuel efficiency and payload capacity. This integration highlights how versatile 3D printing is as it thoroughly revamps the aerospace industry.

What’s even more interesting is that 3D printing supports custom-built rocket components designed for specific missions. This flexibility is key for optimizing performance across different tasks and destinations. The precision of these prints, as pointed out by MSN, provides every piece tailored to convince a balance between weight and strength, which is absolutely crucial for successful launches.

Not only that, but slotting 3D technology into rocket production is paving a path towards more sustainable practices. It cuts down the need for lots of parts and reduces waste, leading to an environmentally friendly approach there, in line with global goals for sustainability, as highlighted by IEEE Spectrum.

Benefts of 3D Printing in Launching Rockets

One huge plus of 3D printing in launching rockets is the ability to whip up rocket parts on the spot. This quick turnaround leads to far more agile space launches since companies can create parts only when necessary—not tied to long, complicated supply chains. According to IEEE Spectrum, having that level of flexibility meets the constantly changing demands of modern space exploration and satellite deployment.

Furthermore, 3D printing drastically lowers production costs by minimizing waste and using fewer materials. As MSN emphasizes, the significant reduction in material costs paired with less overhead for labor over traditional assembly means playing into the hands of economic efficiency in the aerospace realm.

History is already charting successful missions using 3D printed rockets, showcasing the improving reliability and performance of these components. Their success sets the stage for frequent and more accessible future space missions. The face of space exploration is set to change dramatically.

On top of that, the reliability factor can’t be ignored. The seamless nature of 3D printed parts means fewer joints and welds, which reduces chances of malfunction—especially paramount in human-led space missions, where safety dominates the agenda. As cited by MSN, this contributes to overall robustness, vital for handling the challenges of space travel.

Additionally, this flexibility allows designers to iterate their creations rapidly, embracing the fast-paced nature of the aerospace sector apt to constantly redefine itself with new technologies. As IEEE Spectrum suggests, the capability to adapt designs swiftly is critical for keeping one’s edge in the competitive global space scene.

Leaders of 3D Printed Rocket Advancement

Agnikul is taking the lead in the realm of 3D printed rocket engines with innovative strategies. As discussed in IEEE Spectrum, the company manages to produce entire rocket engines as a single unit, minimizing the need for complex assembly and enhancing their reliability. This places Agnikul at the forefront of aerospace innovation.

Many other companies are also all in, with 3D printing gaining traction globally, as businesses hone in on how it can bolster their tunes while eliminating costs. The industry is certainly on the cusp of a whole new innovation era, with 3D printing firmly typifying it, according to MSN.

Collaborative efforts within this space are pushing further cutting-edge three-dimensional printing fuel technology and its impact in rocketry. By sharing know-how and pooling resources, experts can accelerate technology progression and market introduction. It’s collaboration like this that keeps innovation from hitting a roadblock and ensures 3D printing remains a game-changer in the aerospace industry.

Looking Ahead: 3D Printing in Aerospace

The future is super bright for 3D printing in aerospace, with awesome advancements on the horizon that can further industry disruption. Articles by MSN indicate that better materials and printing methods could yield even more efficient and capable components for rockets, paving the way to cool new endeavors in space exploration and commercial use.

Long-term, we can expect 3D printing to majorly influence costs and access to space exploration. By trimming down the expenses related to creating and launching rockets, this tech could truly democratize space, allowing more nations and private entities to join the fray as highlighted by IEEE Spectrum. We’re set to witness an exhilarating chapter of innovation and discovery.

Lastly, let’s not forget the element of sustainability that 3D printing introduces to rocket crafting and space missions. By cutting down waste and optimizing materials, this form of printing spins a greener thread through the manufacturing chain. As the industry forges ahead, expect 3D printing’s role in ensuring sustainability become more central, shaping the quest for space exploration for years to come.